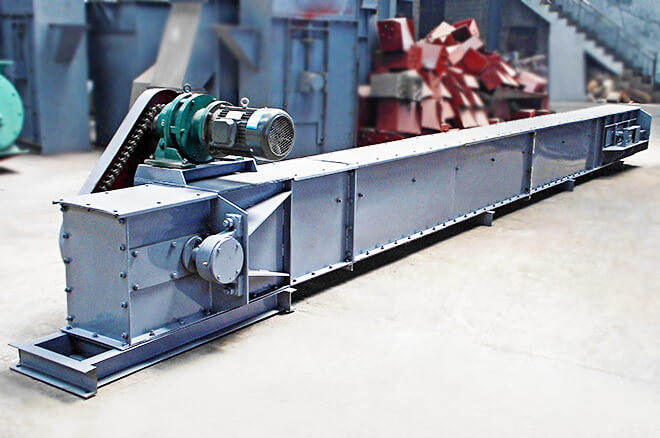

The Drag Conveyor is a conveying device for continuously conveying powder, granules and small pieces of granular materials in a closed casing by means of a moving scraper chain. Since the scraper chain is buried in the material to be conveyed, it is called a buried scraper conveyor.

When transporting horizontally, the material is subjected to the thrust of the scraper chain in the running direction.The material is conveyed forward with the scraper chain to form a continuous overall material flow.

When lifting vertically, the material is lifted by the scraper chain in the moving direction.The continuous feeding of the lower part also causes the falling of the upper material to be subjected to continuous resistance, forcing the material to move upward with the scraper chain.

When these forces are greater than the friction between the material and the shell wall and the weight of the material, the material forms a continuous overall stream that is lifted.

The traction chain has high strength and can be used for long distance transportation.Processes such as sorting, drying, cooling or assembly can be performed during the transport process.

Drag conveyor is simple structure,light weight,small volume and floor space.Easy to produce, install and maintain.

Flexible layout.Horizontally, inclinedly and vertically lift and convey.Continuous operation,multi-point feed and discharge.

Conveying airtight, dustproof, anti-virus, explosion-proof.Ambient temperatures of -20 to +45 °C.

Wide range of applications,sealed conveying.

WHY CHOOSE EXCT Trough/Drag Chain Conveyor

| En-masse Scraper Conveyor Technical Specifications |

| Machine Item |

MS25 |

MS32 |

MS40 |

MS50 |

MS63 |

MS80 |

| Chute Width(mm) |

250 |

315 |

400 |

500 |

630 |

800 |

| Capacity(t/h) |

25/31.5 |

40/50 |

80/100 |

160/200 |

200/250 |

315/400 |

| Max Conveying Distance(m) |

50 |

50 |

50 |

50 |

50 |

50 |

| Scrapper Chain |

Model |

3002T |

3002T |

3003T |

3003T |

3003T |

3003T |

| Allowable load(kn) |

33.4 |

45 |

100 |

100 |

275 |

2100 |

| Weight(kg/m) |

13.87 |

15.36 |

25.34 |

25.34 |

47.6 |

52.32 |

| Operating speed(m/s) |

0.16/0.20/0.25/0.32 |

Material to be processed: ______ Handling capacity: ______ t/h

Bulk Density: ______t/m3 Conveying distance(from inlet to outlet):______ m

Material temperature: ______ ℃; Working environment temperature: ______ ℃

Material is corrosive or not:______ (Ps. Yes or No) Water content:______%

Max. granule size of the feeding material:______mm Max. Granule’s percentage in whole material:______ %

Installation form is horizontal or inclined : ______ ; If it is inclined,what is the inclined degree______°

Upstream equipment (using for feed the material): ______ Downstream equipment (using for discharge the material): ______

Whether needing supporting equipment?______(Ps. Yes or No)

Working power supply: ______ V ______HZ Quantity:______

.jpg)

.jpg)

.jpg)