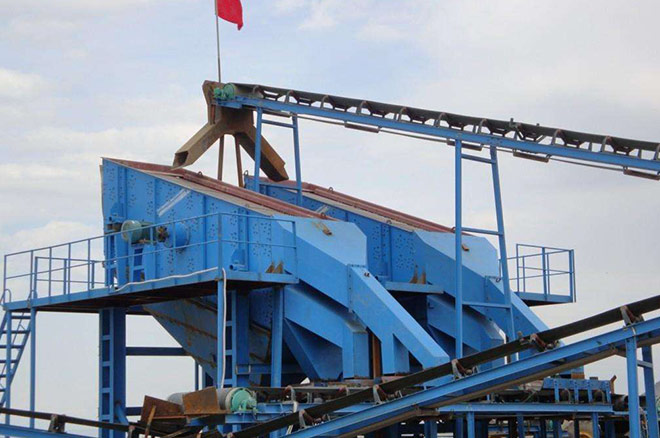

Circular vibrating screen’s shaft line is at the center of gravity, resulting in a circular motion on all points of the screen. Particles are moved forward by the screen motion and gravity effect causing from screen angle. The material’s travel speed is even all along the decks.

The shaft line is made of modular vibrators with flange mounted on the side walls and synchronized by cardan shaft.

The eccentric counterweights of each modular vibrator creating the wanted stroke. We offer vibrators’ exchange program for facilitate the servicing.

.jpg)

| Circular Vibrating Screen Technical Specifications |

| Model |

Layers |

Area

(㎡) |

Angle

(°) |

Mesh size

(mm)

|

Max feed size

(mm)

|

Capacity

(t/h) |

Frequency

(rpm)

|

Power

(kw) |

Overall Dimension

(mm)

|

| YA1236 |

1 |

4.3 |

20 |

6~50 |

≤200 |

75~245 |

845 |

11 |

3757*2364*2456 |

| 2YA1236 |

2 |

4.3 |

20 |

6~50 |

≤200 |

75~245 |

845 |

11 |

3757*2364*2456 |

| YA1530 |

1 |

4.5 |

20 |

6~50 |

≤200 |

80~255 |

845 |

11 |

3184*2670*2280 |

| YA1536 |

1 |

5.4 |

20 |

6~50 |

≤200 |

95~310 |

845 |

11 |

3757*2670*2419 |

| 2YA1536 |

2 |

5.4 |

20 |

6~50 |

≤200 |

95~310 |

845 |

15 |

3757*2715*2419 |

| YAH1536 |

1 |

5.4 |

20 |

6~50 |

≤400 |

240~660 |

755 |

11 |

3757*2670*2437 |

| 2YAH1536 |

2 |

5.4 |

20 |

6~150 |

≤400 |

240~660 |

755 |

15 |

3757*2715*2437 |

| YA1542 |

1 |

6.3 |

20 |

6~50 |

≤200 |

110~360 |

845 |

11 |

4331*2670*2655 |

| 2YA1542 |

2 |

6.3 |

20 |

6~50 |

≤200 |

110~360 |

845 |

15 |

4331*2715*2675 |

| YA1548 |

1 |

7.2 |

20 |

6~50 |

≤200 |

125~410 |

845 |

15 |

4904*2715*2854 |

| 2YA1548 |

2 |

7.2 |

20 |

6~50 |

≤200 |

125~410 |

845 |

15 |

4904*2715*2861 |

| YAH1548 |

1 |

7.2 |

20 |

6~150 |

≤400 |

320~780 |

755 |

15 |

4904*2715*2943 |

| 2YAH1548 |

2 |

7.2 |

20 |

30~150 |

≤400 |

320~780 |

755 |

15 |

4904*2715*2943 |

| YA1836 |

1 |

6.5 |

20 |

6~50 |

≤200 |

115~370 |

845 |

11 |

3757*2975*2419 |

| 2YA1836 |

2 |

6.5 |

20 |

6~50 |

≤200 |

115~370 |

845 |

15 |

3757*2975*2419 |

| YAH1836 |

1 |

6.5 |

20 |

6~50 |

≤400 |

290~800 |

755 |

11 |

3757*2975*2437 |

| 2YAH1836 |

2 |

6.5 |

20 |

30~150 |

≤400 |

290~800 |

755 |

15 |

3757*3020*2437 |

| YA1842 |

1 |

7.6 |

20 |

6~50 |

≤200 |

135~430 |

845 |

15 |

4331*3020*2675 |

| 2YA1842 |

2 |

7.6 |

20 |

6~50 |

≤200 |

135~430 |

845 |

15 |

4331*3020*2675 |

| YAH1842 |

1 |

7.6 |

20 |

6~50 |

≤400 |

340~900 |

755 |

15 |

4331*3020*2700 |

| 2YAH1842 |

2 |

7.6 |

20 |

6~150 |

≤400 |

340~900 |

755 |

15 |

4331*3020*2700 |

| YA1848 |

1 |

8.6 |

20 |

6~50 |

≤200 |

150~490 |

845 |

15 |

4904*3020*2861 |

| 2YA1848 |

2 |

8.6 |

20 |

6~50 |

≤200 |

150~490 |

845 |

15 |

4904*3020*2861 |

| YAH1848 |

1 |

8.6 |

20 |

30~150 |

≤200 |

385~1000 |

755 |

15 |

4904*3020*2943 |

| 2YAH1848 |

2 |

8.6 |

20 |

6~150 |

≤400 |

385~1000 |

755 |

15 |

4904*3020*2943 |

| YA2148 |

1 |

10 |

20 |

6~50 |

≤200 |

175~570 |

748 |

18.5 |

4945*3423*3515 |

| 2YA2148 |

2 |

10 |

20 |

6~50 |

≤200 |

175~570 |

748 |

22 |

4945*3463*3515 |

| YAH2148 |

1 |

10 |

20 |

30~150 |

≤400 |

445~1200 |

708 |

18.5 |

4945*3423*3501 |

| 2YAH2148 |

2 |

10 |

20 |

6~150 |

≤400 |

445~1200 |

708 |

22 |

6092*3463*3501 |

| YA2160 |

1 |

12.6 |

20 |

6~50 |

≤200 |

220~715 |

748 |

18.5 |

6092*3423*3674 |

| 2YA2160 |

2 |

12.6 |

20 |

6~50 |

≤200 |

220~715 |

748 |

22 |

6092*3463*3674 |

| YAH2160 |

1 |

12.6 |

20 |

30~150 |

≤400 |

565~1400 |

708 |

30 |

6116*3619*3849 |

| 2YAH2160 |

2 |

12.6 |

20 |

6~150 |

≤400 |

565~1400 |

708 |

30 |

6116*3619*3849 |

| YA2448 |

1 |

11.5 |

20 |

6~50 |

≤200 |

200~650 |

748 |

18.5 |

4945*3728*3473 |

| YAH2448 |

1 |

11.5 |

20 |

30~150 |

≤400 |

515~1300 |

708 |

30 |

4970*3925*3638 |

| 2YAH2448 |

2 |

11.5 |

20 |

30~150 |

≤400 |

515~1300 |

708 |

30 |

4970*3925*3638 |

| YA2460 |

1 |

14.4 |

20 |

6~50 |

≤200 |

250~810 |

748 |

30 |

6091*3925*3850 |

| 2YA2460 |

2 |

14.4 |

20 |

6~50 |

≤200 |

250~810 |

748 |

30 |

6091*3925*3850 |

| YAH2460 |

1 |

14.4 |

20 |

30~150 |

≤400 |

645~1500 |

708 |

30 |

6091*3925*3846 |

| 2YAH2460 |

2 |

14.4 |

20 |

30~150 |

≤400 |

645~1500 |

708 |

30 |

6091*3925*3846 |

1.Material to be screened: ______(We will appreciate if you can provide us the on-site photo for the material)

2.Handling capacity:______t/h

3.Bulk Density: ______t/m3

4.Max. granule size of the feeding material: ______mm

5.Layer number: ______

6.Mesh size of each layer: ______mm

7.Particle distribution percentage:______

please check the following example to help you undertand it:

If the layer number is two, the mesh size of each layer is 8 mm and 3 mm, then you will get 3 kinds of products: X,Y and Z. X≥8 mm; 3mm≤ Y < 8 mm; Z<3mm.

We want to confirm the following information:

a.The percentage of X in the whole material:______%;

b.The percentage of Y in the whole material:______%;

c.The percentage of Z in the whole material:______%;

8.What equipment is used to feed the material into the circular vibrating screen:______

9. What equipment is used to discharge the material from the circular vibrating screen: ______

10.Working power supply: ______V ______HZ

11.Does the circular vibrating screen work alone or with other equipment to form a system? If forming a system, do you have preliminary design or hand-drawn sketch? If have,Please send it to our engineer for reference.

12.Quantity required :______

.jpg)

-(1).jpg)