Inner Mongolia Coal Preparation Plant is a coal preparation plant with a design capacity of 800,000 t/a, which was completed and put into operation in June 1998. In order to meet the market demand and improve economic benefits, technical transformation projects were carried out for the coal washing plant twice in 2004 and 2005. The annual extraction capacity of raw coal finally reaches 2.6 million tons, and the process is composed of raw coal preparation, heavy medium separation, concentration pressure filtration and other systems. The raw coal is crushed by

mineral sizers and fed directly to the heavy medium cyclone in the main building. mineral sizers were selected as the final check equipment for the raw coal crushing products in the technical reform. It was put into use in November 2006, and after a year of production and operation, remarkable results have been achieved to ensure normal production. The use of mineral sizers is described as follows: The selected raw coal of Inner Mongolia Coal Preparation Plant is the No. 2 coal of the mine, which has been mined for 90 years. Thin coal seam, lots of gangue, complex geological conditions, many gangue layers, poor coal quality, raw coal is aged anthracite), with a grinding coefficient of 30~33 and a large amount of pyrite.

Mineral sizers use the shear principle to make full use of the basic strength characteristics of rock, coal, coke, etc. Compressive strength > shear strength > tensile strength,

mineral sizers shear, pierce and break materials. The old toothed roller crusher is used to crush the material, grinding and other functions, so that it is broken, large materials can be broken after the crushing teeth repeatedly impact extrusion, resulting in too much crushing. And a large number of limited materials that meet the size requirements of the product are also subjected to extrusion and grinding, making it more serious. Mineral sizers use low speed and high torque to make the material pass through at one time, which reduces the repeated extrusion and grinding of the material by the crushing teeth and reduces the over-crushing rate. The above crushing mechanism greatly improves the processing capacity of the equipment and reduces the over-crushing, so as to better ensure the block formation rate of the product.

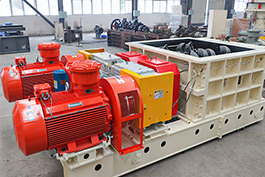

The structural form mineral sizers consists of three parts: The body, the intelligent measurement and control system and the centralized lubrication system. The body is mainly composed of frame, bearing seat cover, transmission system, crushing roller parts and shell.

(1)Mineral sizers frame is made of multi-layer steel plate welded, bearing seat covers are cast steel, to ensure mechanical strength, smooth operation.

(2)

Mineral sizers drive system adopts planetary gear drive, mainly composed of motor, hydraulic coupler, safety pin. The two-tooth roller is driven by two motors separately, and the coupling of the two motors with high and low speed directly drives the tooth roller respectively, which has less fault points and less maintenance, which can reduce the speed of the tooth roller, and has a larger energy storage function, reduce the installed power of the equipment, and realize energy saving and consumption reduction.

.jpg)