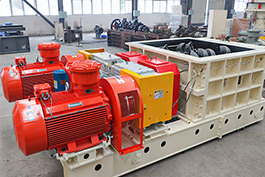

Mineral sizers are mainly composed of gear boxes, frame parts, fixed rolls, movable rolls, linkage devices, etc. The toothed crushing plate is the main part of the fixed stick, and the toothed crushing plate is in direct contact with the ore, which requires the high hardness of the toothed crushing plate. Therefore, the tooth crushing plate is selected to contain chromium high manganese steel, and the water toughening treatment is carried out after casting. Because the fixed roller work is to keep rotating, the fixed roller allows a small allowable eccentricity, so the roller core must do static balance test. In order to ensure that the tooth crushing plate and spare parts can still ensure the static balance after installation, the weight difference of the tooth crushing plate shall not be greater than 1kg, so the tooth crushing plate must be processed. Due to the high hardness, the tool cutting heat is too large, if not timely heat will make the tool annealing. It affects processing, so the speed of the equipment is very low during processing. The general processing method is the gantry milling machine, the crushing plate (referred to as the tooth plate) four corners cushion, so that the tooth plate tooth tip does not contact the bed, four corners and then with four pressure plates, and then processing, because the tooth plate pressure plate processing, so after processing, the remaining surface (pressure plate compression) need to move the pressure plate, the remaining part continue to process, due to the hardness of the tooth plate, the tool speed cannot be too fast, so the processing period is particularly long, and the tooth plate is the key part of the entire equipment, the loss is large, the quantity demand is large, so this ordinary processing method cannot meet the needs of production. To improve the processing efficiency of the tooth plate, that is, to ensure the processing quality, but also to improve the processing efficiency has become a key point, we start from these two points, the processing method has been improved to solve this problem.

1. The design of processing fetal gear

Mineral sizers tooth plate machining method mainly solves the problem of tooth plate loading, which is convenient to locate, but also makes it complete after loading once, no need to repeat loading, in order to better improve the processing efficiency, combined with the existing equipment, we choose double column milling processing, so that our processing efficiency will be greatly improved. Starting from the above two points, we design a symmetrical device, so as to ensure that the device can be used on the double column mill, the rest we solve is the problem of loading the card, that is, it can be stable, but also make it easy to find the right, so we design the loading surface into the arc of the same arc loading surface as the tooth plate, and design a hook slot below, the hook slot is used to jam the lower end of the tooth plate. The hook groove is designed strictly in accordance with the prototype of the lower end of the tooth plate, so that the tooth plate is well installed on the device, because the tooth plate is a casting, the casting may appear the phenomenon of box swell and so on, so that the arc surface of the tooth plate and the fixture arc are not shaped, the design of the device has a top wire for fine tuning to make the alignment more accurate, the top wire is divided into four positions, one at each end of the device. This will make the search easier. When processing, it is necessary to fix the device on the bed surface, we choose the lower part of the device with a key block, the key block is combined with the bed groove, and then use three bolts to fix the device, when fixing the tooth plate, you need to use a pressure plate, in order to ensure that the pressure plate presses the two pieces of tooth plate, the two pieces of tooth plate does not expand to both sides, we design the pressure plate is both ends of the inclined surface pressure plate, so that when pressing, there will be two pressing forces to the middle, so as to ensure the expansion of the tooth plate, and we use the bolts of the fixing device to fix the pressure plate, so that a number of bolts are subtracted, so that the use of the birth gear is not cumbersome.

2 Tooth plate processing of the design process

Mineral sizers kits consist of a positioning key at the bottom of the base plate, a support tube and a side plate between the bottom plate and the upper plate, a hook groove at the bottom of the outer side of the side plate, and a top wire respectively arranged on both sides of the side plate and the two sides of the upper plate: the upper part of the bolt in the support tube is a pressure plate, the bolt above the pressure plate is provided with a positioning nut, and the bolt between the pressure plate and the upper plate is provided with a nut. The bottom surface of the pressure plate can be an inward inclined surface: so that the tooth plates on both sides are inward, which is more conducive to the fixing of the tooth plate. The outer side of the side plate is the same arc surface of the tooth plate processing: so that the tooth surface is fitted to the side plate, easy to fit, more conducive to processing. The main clamping step of double-column milling is: first, the fixed fixture is stuck on the double-column milling machine surface, centered as far as possible: the key block is in the groove of the bed surface, the use of bolts to press, then there is no need to find the right, the key block has achieved the accuracy of the straight direction; then the lower end of the hook surface of the tooth plate is stuck in the hook groove of the fixed fixture, the upper pressure plate is pressed on, and the pressure is not pressed temporarily: the top wire is used to find the right, and the pressure plate is pressed after the right, and then the processing can be carried out. Description of results: because the processing method adopts the key block positioning on the bottom of the fetal, the hook groove is installed with the clamping plate, the inclined plate is pressed, and the top wire is fine-tuned, the clamping method has stable teeth and high precision during processing, which can ensure the quality of the product. Because the processing method is simple and convenient to clamp on the machine tool, after loading the card once, there is no need to install the card to find the right fetal, and it can process two workpieces at the same time, so it solves the problem that the conventional method needs to load the card repeatedly, and greatly improves the production efficiency.