New

mineral sizers is a kind of crushing equipment with many unique advantages in recent years. In order to provide reasonable and reliable theoretical basis for its design and series development, the calculation method of its production capacity is studied in this paper, and the formula for calculating the production capacity of this kind of crusher is derived, and the experiment is carried out on the simulated crushing experimental machine. It is proved that the formula has universal significance for several new double-toothed rod crusher series products with different parameters.

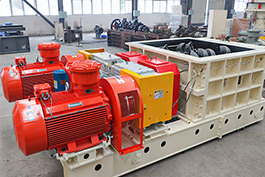

The brittle materials crushed in our country each year reach more than 1.8 billion t, and the power consumption, steel consumption and raw material consumption in the crushing process are great, therefore, the development of a large crushing ratio and high efficiency and energy saving crusher has important and far-reaching significance. In the late 1980s, British MMD company successfully developed a completely new type mineral sizers, which has the unique advantages of strong crushing ability and low power consumption. 16 large-scale mineral sizers have been introduced in Antaibo Coal Mine, Datong Coal Mine and Junger Mine in China, and obvious economic benefits have been achieved). However, for the majority of small and medium-sized enterprises, especially rural township enterprises, the price of imported products is expensive and difficult to bear. Therefore, it is imperative to carry out theoretical and experimental research on this kind of crusher in order to carry out mass and serial production. Production capacity is an important basis for users to choose a crusher, and it is directly related to the selection of various parameters in the design of the crusher, such as the power of the motor, the length of the crushing chamber, etc. We designed a new mineral sizers prototype as the research object. Through theoretical analysis and experimental research, the determination method of its production capacity was studied. It provides a reasonable and reliable theoretical basis for the design and series development of new mineral sizers.

.jpg)

Crusher production capacity in addition to the crusher's own parameters, but also affected by the nature of the material, the degree of looseness of the material, the adequacy of the feed and other factors, therefore, the actual production capacity fluctuates greatly, it is difficult to use an accurate formula to describe. In the long-term production practice and research, several formulas for calculating the production capacity of roll crusher have been obtained, but they are all empirical formulas obtained in the application of roll crushers, suitable for roll crushers with clean rolls or smaller teeth. The new mineral sizers are fundamentally different from traditional roll crushers. Therefore, the use of these formulas can lead to significant errors. The new

mineral sizers act on the material as follows: 1) When the rolling teeth in motion suddenly encounter a large material, the staggered tooth tips will first impact and shear the material. The broken material is bitten by the teeth. If the material is not broken under the impact, the spiral arranged teeth will turn the material over and wait for the next pair of teeth to continue to act. This crushing section is from. Materials are broken between teeth by the combined action of shear and extrusion, and the broken and extruded materials leak directly from the gap at the side of teeth, that is, this stage is the process of crushing and discharging materials at the same time., this crushing stage is the process of tooth movement from position 2-2 to position 3-3'. From the tooth movement to the position 3-3, when the first pair of teeth break off from the bite, the inclusion area between the teeth begins to increase from the minimum, the materials broken by the second stage are swept out by the current pair of teeth, and the materials meeting the discharge particle size are directly discharged from the split bar's convex gap, while the materials with individual particle size is still too large are blocked by the split bar. 3) The individual material with large particle size that is blocked on the splitting rod is acted on by the rolling teeth running down with the splitting rod, and is further broken by impact, shear and bending and forced out. It can be seen that most of the broken material in mineral sizers is broken and discharged as a result of being bitten by the teeth. Only a small part of the material is leaked through the top and side of the teeth. The fundamental reason why the traditional formula is not suitable for the production capacity calculation of the new

mineral sizers is that the special large teeth and forced discharge mechanism are not taken into account.

.jpg)