Mineral sizers are a kind of equipment that breaks materials by cutting, which has the advantages of large crushing ratio, good crushing effect, low powder formation rate and a wide range of materials.

At present, the mineral sizers used in China are mainly in the following aspects:

① Small crushing ratio, discharge particle size cannot be adjusted. mineral sizers work on the principle that the size of the discharge particle is determined by the three-dimensional space of the intersected tooth shape of the two toothed rollers. When a smaller discharge size is required, the tooth shape is designed to be smaller, thus limiting the feed size from being too large: In addition, due to the existence of a variety of uncertain factors in the on-site material (such as water content, material strength, material size, etc.), it is easy to appear the material discharge particle size phenomenon, the solution needs to redesign the tooth plate: when the equipment is used for a long time, due to the tooth plate wear caused by the discharge particle size is poor, at this time also need to replace the tooth plate, because the tooth plate is expensive, increasing the customer's use cost.

The fixing method of the tooth plate is not reliable. Due to the use of bolt connection, the bolt is stretched and broken under the repeated action of torsional force and impact force, and it is easy to cause equipment damage when the tooth plate falls off.

③ Most of the tooth plate materials are made of high manganese steel, which has a limited service life and cannot be repaired after wear, and it is expensive to replace the tooth plate. Fourth, because the gear roller and the reducer are often connected by the gear coupling, the noise is large and the maintenance is inconvenient.

The technical problem to be solved is to overcome the shortcomings of the prior art and provide a strong

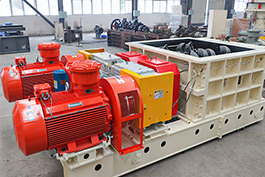

mineral sizers equipped with secondary crushing device, which has the advantages of adjustable discharge particle size, compact structure, large crushing capacity, reliable tooth plate fixing, easy maintenance, low cost, low noise, easy installation and debugging. The technical solution adopted to solve the technical problem is: a strong mineral sizers equipped with a secondary crushing device comprises a base and a crushing system, under which a secondary crushing device crushing beam is installed and an adjusting pad is arranged at the bottom of the crushing beam; The crushing system comprises two sets of tooth roller crushing units, each set of tooth roller crushing units comprises a motor, hydraulic coupler, reducer, elastic pin coupling, tooth roller and tooth roller, the motor is connected with the reducer through the hydraulic coupler, the reducer through the elastic pin coupling to drive the tooth roller to rotate, the tooth roller is distributed on the staggered arrangement of crushing teeth. The tooth roller comprises a tooth roller shaft, a tooth plate seat, a tooth plate, a round nut, a tensioning screw and a wedge block, and the tooth plate is fixed by a wedge block tensioning method. The elastic pin coupling comprises a tooth roller end half coupling, a reducer ends half coupling, an elastomer and a pin, the reducer and the tooth roller are equipped with a half coupling at both ends, the pin end is installed on the half coupling, and the other end is installed with the elastomer. By adding a secondary crushing device to solve the problem of small crushing ratio and adjustable discharge particle size, the tooth roller is driven by a double motor to break the material, and the two tooth rollers rotate to the center of the equipment. The shear force and tensile force are applied to the material through the staggered crushing teeth distributed on the tooth roller. The tooth roller drives the material to act on the broken beam to achieve the second crushing. Due to the use of secondary crushing, a larger tooth shape can be designed in the primary crushing to break larger materials. The discharge particle size is controlled by the crushing beam of the secondary crushing device, so that a larger crushing ratio can be obtained. A cushion block is installed under the broken beam, and the discharge particle size can be adjusted by adjusting the height of the cushion block. When using the equipment, customers can adjust the height of the pad according to the actual situation of the material on the site to obtain the required material particle size. This method can also be used to adjust when the tooth plate is worn and the discharge particle size is larger, which improves the utilization rate of the tooth plate and reduces the operating cost of the mineral sizers.

The new type of tooth roller is mainly composed of tooth roller, tooth plate seat, tooth plate, round nut, tension screw and wedge. The assembly method is to design shaft shoulder at one end of the spindle and screw thread at the other end. The tooth plate seat is pressed on the spindle by special equipment and locked by double nut. The tooth plate and the tooth plate seat are fixed by a unique wedge fixing method. The tightening screw pulls the wedge close to the tooth plate seat and the tooth plate, and the torsion force and impact force generated when the tooth plate breaks the material are transmitted by the wedge to the tooth plate seat, avoiding the phenomenon of the screw being directly forced and then broken. In addition, this fixing method of the wedge also has the advantages of convenient installation, reliable fastening and rapid disassembly. The new type of elastic pin coupling is connected by pin and two half couplings. The pin is elastic, can compensate the relative displacement of two axes, and has the function of cushioning and absorbing shock. At the same time, the elastic pin coupling also has the advantages of light weight, easy installation, low noise and maintenance-free. The new crushing ratio can be adjusted according to the actual material condition on site, and the expected discharge particle size can be reached. The new type of wedge tensioning method can solve the phenomenon of "dropping tooth plate" when the tooth plate is connected by bolts, which is easy to install and reliable to fasten. The tooth plate is made of new wear-resistant alloy material with long service life. The motor and the reducer are connected by an elastic pin coupling, which can compensate the displacement of the two axes and also have the effect of cushioning and absorbing shock.

Mineral sizers, through long-term use in coal mines, have the advantages of strong ability to eat large pieces, low powder rate, uniform discharge particle size, safety and reliability, and few faults.