1) According to the process layout,

coal roller screen can be divided into left installation and right installation. Along the direction of the coal flow, the motor reducer on the left side is the left installation type, and the motor reducer on the right side is the right installation type. 2) Before installation, set the embedded parts according to the requirements of the equipment foundation diagram, and check the levelness of the embedded parts. The coal roller screen is delivered for the whole machine. After the equipment is in place, adjust the center of the coal roller screen and the base center to be consistent, weld the base and the embedded part firmly, and grouting twice, so that no coal powder leaks between the base of the coal roller screen and the foundation. Inclined coal roller screen test is divided into two stages of no-load operation and load operation, and the load operation can be carried out after the no-load operation is normal.

1) No load operation. Before the trial run, check whether the reducer and bearing seat are lubricated enough), and then remove the debris on the screen surface, and then start running first, and then run continuously after normal operation. At this stage, each reducer and screen shaft should rotate flexibly, and the temperature rise of each bearing should be normal, otherwise it should be stopped immediately for inspection, and the test can continue until normal.

2) Load operation. No load operation for 2 hours after no abnormal operation, load operation can be carried out. When the load is running, the equipment should be started first and then the load should be added. If any abnormality is found or the test is over, the load should be withdrawn first and then stopped. Operation and maintenance of inclined Coal screen should be interlocked with coal conveyor belt machine running, start the coal screen first, then start the belt machine; Stop the belt machine first, then stop the coal screen machine. After the coal screen is put into operation, the lubrication of each lubrication part should be regularly checked, and the lubricating oil should be regularly supplemented and replaced. The bearing seat is lubricated with calcium grease, and the replacement cycle is half a year. Main technical parameters of inclined

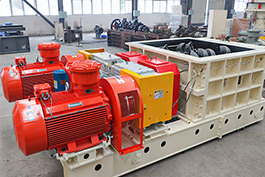

coal roller screen Main technical parameters Screening coal, coke, limestone, etc.) : Rated output 1500th, screening efficiency ≥90, shaft number 10, screen f hole size 45×100mm, feed particle size ≤350mm, mass 15135kg, sieve size ≤40mm, sieve shaft rotation number 90n/min, overall size 5220mm×2980mm×2250mm; R77DV112M4-SRD-3kW motor reducer is adopted, and the supporting motor is provided by the reducer manufacturer.

In summary, coal roller screen, as an important part of coal transport equipment in power plants, although the operating conditions are complex, its inherent regularity can still be found through detailed understanding of the operation principle, selection structure, equipment installation, test run, operation and maintenance of inclined roller screen. The selection method of coal roller screen is summarized to provide guidance for the power plant to select efficient, energy-saving, safe and reliable

coal roller screen.