Mineral sizers The pulverization of mineral sizers is an essential industrial link in the rapidly developing economic society. In the processing of various metal, non-metal, chemical mineral raw materials and building materials, crushing operations consume huge energy, and it is an inefficient operation. In the crushing process of materials, due to the effects of sound, heat, vibration and friction generated in the operation process, a large amount of energy is consumed. Therefore, for many years, researchers have been studying how to achieve energy saving and efficient crushing and grinding processes. From the research of crushing theory to the innovation of crushing equipment (including the transformation of old equipment) to the change of crushing production process.

At present, the research of crushing theory, process and equipment mainly focuses on:

(1) Study the theories of energy saving and high efficiency in crushing, and strive to find new theories to break through the three well-known crushing theories:

(2) Research on new non-mechanical crushing force of high-energy or multi-force field combined crushing machinery and equipment, there is no industrial equipment, only in the research stage:

(3) The improvement of the existing equipment, which is often carried out according to the user's own needs, and not the large-scale production or development of new crushing equipment on the market. For many of the above problems, due to the slow development of foreign mines since the 1980s, the progress in this area is not great. Foreign new equipment is also less, domestic large state-owned mine investment is very little, there is no big development, and small and medium-sized mines due to the demand for raw materials in different places, but in recent years has been a certain development.

Now some industrial crusher according to its structural form can be divided into jaw crusher, jaw roll crusher, vibrating jaw crusher, vibrating crusher, rotary crusher, high pressure roll crusher, cone crusher, impact crusher, impact crusher, hammer crusher,

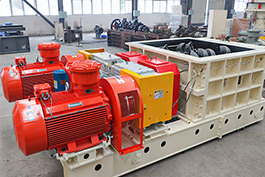

mineral sizers, vertical shaft crusher and many other categories: According to the particle size requirements of the product after crushing, it can be divided into coarse crushing, medium crushing, fine crushing and fine crushing. In many coal preparation plants in our country, mineral sizers have been widely used for their simple structure, reliable operation and low cost.

mineral sizers can be divided into single-tooth roller crushers according to the number of crushing teeth rollers, mineral sizers are mainly used for primary and secondary material crushing.