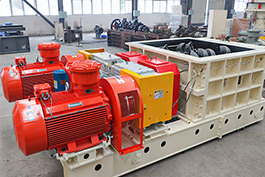

Feeder breaker is a set of crushing, conveying, feeding as one of the comprehensive crushing equipment, mainly used in mining, coal, chemical and other fields, this is our customer sorted out some knowledge about feeder breaker questions and answers.

Requirements for crusher housing

- The crusher housing shall be a fully welded structure.

- Steel structure shall be designed for cold operational conditions.

- The steel quality shall be S355J2+N or equivalent.

Wear plates requirements

- Wear plates shall cover the entire interior of the housing. Wear plates shall be made of abrasion resistant steel with a hardness of at least 450HB.

- Wear plates shall be easily replaceable and shall be designed such that they can be bolted from outside the housing.

Dust protection requirements

Dust protection covering shall be considered what means during the operation the dust generation shall be minimized according to local environmental and safety standards.

Space between teeth and chain feeder surface

300mm(As explained before, the spacing cannot be adjusted)

General requirements for shaft

Shaft shall be designed for fatigue resistance incorporating large radius transitions at changes of section and minimizing any notch effects due to keys or splines. The shaft shall be machined from high strength alloy steel.

Bearing lifetime

Bearings shall be heavy duty, anti-friction type and shall have a basic rating life at least 40.000 hours for bearing loads encountered at design duty

General requirements for the bearing

For the main crusher roll bearings, self-aligning roller bearings with Taconite sealing shall be used, housed in heavy duty fabricated housings. Labyrinth seals shall be fitted to the bearing housings from the both sides of bearing.

Drive unit general requirements

- The drive units comprise of an electric motor, a fluid coupling and a gearbox, connected to the crusher shaft by curved tooth couplings.

- Belt drives are not acceptable.

- Drive unit is mounted onto a common base frame together with the crushing unit (housing with roll).

- In order to ensure availability of spare parts, all mechanical components will be from standard vendor parts to ensure worldwide 24h service and availability.

Power supply

Frequency controlled

EXCT reply:The motor used for crushing is a fixed frequency motor, the starting mode is soft start or frequency conversion start.

But speed regulation cannot be achieved by frequency conversion.

General requirements for the gear boxes

- The gearbox on the roll shall be identical to other gearboxes in order to reduce the required capital spares.

- All gearboxes shall be designed/selected with an application factor of min. 2,75 based on the nominal motor power.

Type of lubrication system

- The crusher shall be fitted with lubrication lines that tie into one central lubrication system for easy greasing.

- If the central lubrication system does not work, the force-feed lubrication system shall be considered as a reserve system for greasinga

The above is our customized feeder breaker for our customers common knowledge questions and answers, we are a professional manufacturer of

feeder breaker, we have advanced processing equipment and production technology, perfect after-sales service and strict quality testing process. We provide you with quality products and services.