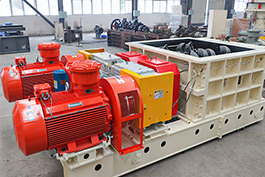

Mineral sizer tooth plate, made of zgmn13, is a group of 6 pieces, the raw material is wrapped in a circle, and the raw material is broken by rotation. Although the impact is not large, but because of the requirements of the broken particle size is small and uniform, the design and use of the surface of the nail, the shape is strange, the wear is large, and the requirement has a high precision and the quality of the casting teeth.

Main casting process analysis:

1, sand analysis: From the shape and more high-precision assembly can be seen, the use of ordinary clay sand, due to the difficulty of repair and can not ensure the shape of the tooth surface and assembly accuracy, self-hardening sand must be used. The commonly used self-hardening sand in our section is c02 water glass sand with quartz sand as the main material. Because it is acidic sand, it is easy to produce chemical sticky sand in high manganese steel casting, which needs to be solved by brushing thicker manganese steel paint. And we can see that the tooth part is not only difficult to brush, and it is easy to cause paint accumulation in the tip of the tooth that is difficult to clean, so that the finished tooth after pouring is not full. Therefore, sand species which are the same as high manganese steel should be selected as far as possible to avoid thick brush paint. Such sands are mainly chromite ore and magnesium olivine sand. Chromite ore particle size is fine and uniform, has high molding capacity and fire resistance, so it is easy to get high surface quality, high dimensional precision castings. However, its price is expensive, and a large number of uses will cause high production costs of castings. The forming ability of magnesium olivine sand is poor because of the poor roundness and uneven particle size. Its fire resistance is also lower than that of chromite ore (higher than quartz sand). However, because of its relatively cheap price, it is more widely used in high manganese steel casting. Therefore, this trial production mainly uses magnesium olivine sand as the main material of c02 water glass sand. The core of the four assembly holes is made of c02 water glass sand with chromite ore as the main material.

2,

Mineral sizer parting surface: According to the structure, this parting surface is only selected on the circular arc surface of the tooth root, the first plan is the tooth face up, the second plan is the tooth face down. Tooth upward is not only difficult to fill, and because of the hard sand is not easy to tie the air hole, resulting in the cavity tooth exhaust difficulty and insufficient pouring. All make the casting teeth full degree is not good. Therefore, the teeth should be selected to face down:

3, Riser: According to the structure, this piece of riser on the top surface is difficult to gas cutting grinding, coupled with high manganese steel paste solidification, the choice of side riser is more suitable. Therefore, the use of two side risers placed on the two ends is conducive to feeding and gas cutting grinding:

4,

Mineral sizer tooth plate paint: Choose magnesium olivine alcohol paint, note that in order to prevent the accumulation of tooth tip paint, the paint must be thin, difficult to control, do not brush paint:

Production results: mineral sizer The tooth plate produced by the above method has smooth surface, high precision assembly dimension and clear and full teeth. Through the feedback of user information, the assembly and use effect are particularly good.

Experience: 1. C02 water glass self-hardening sand of magnesium olivine sand is suitable for casting small and medium-sized high-manganese steel parts with high dimensional accuracy, smooth surface, and more sharp corners, small grooving structures that are not easy to paint:

2, the mineral sizer small deep holes, small deep trenches and other structures of high manganese steel parts are made of c02 water glass self-hardening sand of chrome-iron ore, which can better ensure the casting accuracy and prevent the sand from "Burning" :

3, the small pointed structure of the casting, in the self-hardening sand casting, should be as far as possible to adopt the downward scheme, so as to ensure the pointed structure shape and full degree.