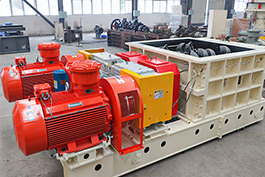

In a

mineral sizer, key connections are used between the ring teeth and shafts. Key connections are a common mechanical connection method, mainly used to achieve circumferential fixation between the shaft and the parts on the shaft (such as gears, pulleys, couplings, etc.) and to transmit torque. According to different structures and functions, key connections can be divided into various types, each with its specific application scenarios and assembly requirements.

Why are key connections used in mineral sizer equipment?

As the most important component of the mineral sizer equipment, it bears high torque and strong impact resistance. Therefore, our

mineral sizer uses key connections between the ring teeth and shafts, which have the following advantages:

1. Efficient and stable power transmission

Strong torque carrying capacity: Key connections (such as splines, flat keys) can accurately transmit the motor's power to the toothed roller shaft, ensuring stable operation under high-torque conditions, especially suitable for the impact loads when crushing hard materials (such as ores, rocks).

Synchronous transmission design: Grading crushers usually contain multiple sets of toothed rollers. Key connections can ensure that the rotational speeds of each set of toothed rollers are synchronized, avoiding material blockage or excessive wear caused by speed differences.

2. Compact structure and convenient maintenance

Modular design: The standardized structure of key connections facilitates the quick disassembly and assembly of components such as toothed rollers and bearings, reducing downtime for maintenance. For example, the use of expansion sleeves or taper sleeves for connection can achieve keyless installation, simplifying the maintenance process.

Adaptation to complex working conditions: The multi-stage design of the grading crushing chamber requires the transmission system to flexibly respond to the crushing demands of different areas. Key connections ensure precise positioning and reliable fixation, maintaining the stability of the toothed rollers under high-frequency vibration.

3. High reliability and durability

Fatigue resistance: Key connections made of high-quality materials (such as alloy steel) can withstand long-term alternating loads, reducing the risk of fracture and extending the equipment's lifespan.

Wear resistance: Surface quenching or carburizing treatment of keyways and key blocks can effectively resist wear from dust and material particles, reducing the probability of transmission failure.

4. Adaptation to the grading crushing process

Flexible speed adjustment: Key connections support the adjustment of the transmission ratio between the toothed roller shaft and the motor, adapting to the speed requirements of different crushing stages (coarse crushing, medium crushing, fine crushing) and optimizing the crushing efficiency.

Overload protection: Some key connection designs (such as safety pins) can break in advance during sudden overloads, protecting core components from damage and reducing maintenance costs.

5. Economic and environmental benefits

Energy saving: Stable transmission efficiency reduces energy loss, making it more energy-efficient compared to traditional connection methods (such as belt drives).

Pollution reduction: The sealing design of key connections prevents lubricating oil leakage, avoiding environmental pollution and reducing the spillage of material dust.

After adopting key connections, the

mineral sizer can achieve efficient and precise power transmission, enhance its impact resistance and wear resistance, and prevent shaft breakage and slippage.