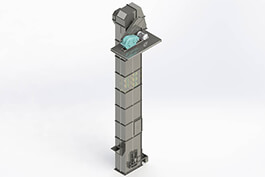

The hopper picks up the material from the underlying storage, and as the conveyor belt is lifted to the top, it rolls over the top wheel and then flips down. The bucket elevator pours the material into the receiving tank.

The drive belt of the belt bucket elevator with belt drive is generally equipped with rubber belt, which is mounted on the lower or upper drive roller and the upper and lower redirection rollers. Belt bucket elevator: suitable for lifting from low place to high place. The supply material is automatically transported upwards and continuously after the material is put into the hopper through the vibrating table.

High capacity vertical conveying

It adopts inflow feeding, inducing unloading, and large-capacity hopper intensive arrangement. There is almost no returning and excavation during material lifting, so there is less reactive power.

Extra heavy-duty design

The Bucket Elevator has less requirements on the type and characteristics of the material, not only can improve the general powdery and small granular materials, but also can improve the materials with high abrasion resistance. The sealing performance is good and the environmental pollution is less.

Highly reliable and durable

The operation reliability is good, the advanced design principle and processing method ensure the reliability of the whole machine operation, and the trouble-free time exceeds 20,000 hours. The lifting height is high. The hoist runs smoothly, so it can reach a higher lifting height.

Long service life

The feeding of the hoist is inflow type, no need to use the bucket to dig, and there is little squeezing and collision between the materials. The machine is designed to ensure that the material is less sprinkled during feeding and unloading, reducing mechanical wear.

why choose exct belt bucket elevator

|

HEAD SECTION DRIVING DEVICE

The standard configuration adopts the orthogonal shaft reducer and the fluid coupling, and is equipped with a backstop device. The transmission structure is compact and the flexible transmission is realized. It can not only stabilize the operation, but also protect the motor, reducer and traction parts.

|

| MIDDLE SECTION

The head, tail and middle casing of the machine are effectively sealed, and the materials and dust are not raised, which will not cause environmental pollution.

|

.jpg) |

.jpg) |

BOTTOM SECTION

The tail section is used to support the entire elevator and is the location of the feed. It consists of a feed port, a lower casing, a tension roller set and a tensioning device.

|

|

ELEVATOR BUCKET&BELT

Here are mainly steel buckets and high molecular polyethylene buckets, as well as shallow buckets, deep buckets, guide buckets, combination buckets, dewatering buckets, etc., which can be selected according to material characteristics and unloading methods.

The bucket elevator can be equipped with a tear-resistant steel cord conveyor belt as the traction member, which has good toughness and high strength.

|

|

|

TENSIONING DEVICE

Fabricated of heavy plate with manganese or AR alloy steel wear liners, are supported by vertical columns on the main sill beams and can have cover plates to enclose conveyed material.

|

| Belt Bucket Elevator (Deep bucket) Technical Specifications |

| Model |

TDG160 |

TDG200 |

TDG250 |

TDG315 |

TDG400 |

TDG500 |

TDG630 |

TDG800 |

TDG1000 |

TDG1250 |

TDG1600 |

| Capacity(m3/h) |

32 |

45 |

72 |

101 |

158 |

220 |

348 |

492 |

788 |

1220 |

1541 |

| Bucket |

Volume(L) |

2.6 |

4.1 |

6.5 |

10 |

16 |

25 |

40 |

64 |

102 |

161 |

255 |

| Pitch(mm) |

260 |

300 |

325 |

360 |

420 |

460 |

520 |

580 |

650 |

720 |

820 |

| Belt&bucket weight(kg/m) |

22 |

21.5 |

33 |

33.2 |

42.2 |

62.3 |

78.53 |

106 |

145 |

155.5 |

223 |

| Speed(m/s) |

1.2 |

1.2 |

1.34 |

1.34 |

1.5 |

1.5 |

1.68 |

1.65 |

1.86 |

1.86 |

1.836 |

| Max lift height(m) |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

| The capacity is calculated by the filling factor k=0.75 |

| |

| Belt Bucket Elevator (Shallow bucket) Technical Specifications |

| Model |

TDG160 |

TDG200 |

TDG250 |

TDG315 |

TDG400 |

TDG500 |

TDG630 |

TDG800 |

TDG1000 |

TDG1250 |

TDG1600 |

| Capacity(m3/h) |

24 |

31 |

51 |

74 |

118 |

167 |

253 |

361 |

571 |

816 |

1112 |

| Bucket |

Volume(L) |

1.9 |

2.9 |

4.6 |

7.4 |

12 |

19 |

29 |

47 |

74 |

117 |

184 |

| Pitch(mm) |

260 |

300 |

325 |

360 |

420 |

460 |

520 |

580 |

650 |

720 |

820 |

| Belt&bucket weight(kg/m) |

22 |

21.5 |

33 |

33.2 |

42.2 |

62.3 |

78.53 |

106 |

145 |

155.5 |

223 |

| Speed(m/s) |

1.2 |

1.2 |

1.34 |

1.34 |

1.5 |

1.5 |

1.68 |

1.65 |

1.86 |

1.86 |

1.836 |

| Max lift height(m) |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

| Remark:The capacity is calculated by the filling factor k=0.75 |

1.Which material to be handling:______

2.Handling capacity:______t/h.

3.Lifting height of bucket elevator = : ______m

4.Bulk Material Density: ______t/m3

5.Max. granule size of the material: ______mm

6.Max. granule’s percentage in whole material:______ %

7.Material temperature:______℃

8.What equipment is used to feed the material into the belt bucket elevator:______

9.What equipment is used to discharge the material from the belt bucket elevator:______

10.Working power supply: ______V ______HZ

11.Quantity:______

12.As everyone knows, the belt bucket elevator work with other equipment to form a process system, therefore, we will appreciate if you can provide us the preliminary design or hand-drawn sketch of the process system for our engineers reference.

.jpg)

.jpg)

.jpg)