EXCT supplies high-performance bucket elevators with central chain for high conveying capacities and tall centre distances. All elevators provide a close bucket pitch. Thus the bulk material is feed directly to the buckets and scooping of bulk material from the elevator boot is avoided to a maximum extend. The discharge of bulk material at the elevator head is affected by means of centrifugal force. A friction drive between the segmented drive ring and the central chain provides the torque transmission and allows velocities.

If you need elevator buckets, please click: https://www.exctmach.com/products/spare-parts/elevator-buckets.html

- Material flow with minimal spillage due to closely arranged buckets

- Suitable for abrasive, hot, coarse and fine materials

- High capacity, long service life,minimal operational costs,hermetically sealed against dust and gas

- Heavy-duty design: heat-resistant and wear-resistant, even with abrasive materials

- Stainless steel can be used if needed

- The drive wheel adopts no-tooth friction drive to ensure smooth operation of the equipment.

- Perfect, specific and scientific manufacturing process ensures high precision of every part of the chain

- The structure is made of forceps hardened steel bearings and tail weight. This structure is low investment, convenient maintenance and replacement, and high equipment reliability. Therefore the operation is reliable, stable, low noise, and good sealing performance.

| Central Chain Bucket Elevator Technical Specifications |

| 304.7 Series Single chain & bucket |

| Model |

Bucket width(mm) |

Volume(L) |

Distance |

Speed(m/s) |

Capacity(m3/h) |

Speed(m/s) |

Capacity(m3/h) |

| ZYL280 |

280 |

8.9 |

304.7 |

1.28 |

100 |

1.42 |

110 |

| ZYL500 |

500 |

15.5 |

304.7 |

1.28 |

175 |

1.42 |

195 |

| ZYL630 |

630 |

19.5 |

304.7 |

1.28 |

220 |

1.42 |

245 |

| 355.6 Series Single chain & bucket |

| Model |

Bucket width(mm) |

Volume(L) |

Distance |

Speed(m/s) |

Capacity(m3/h) |

Speed(m/s) |

Capacity(m3/h) |

| ZYL500D |

500 |

29 |

355.6 |

1.68 |

340 |

1.86 |

380 |

| ZYL600 |

600 |

35 |

355.6 |

1.68 |

440 |

1.86 |

490 |

| ZYL720 |

720 |

41.9 |

355.6 |

1.68 |

530 |

1.86 |

590 |

| ZYL800 |

800 |

46.6 |

355.6 |

1.68 |

590 |

1.86 |

660 |

| ZYL900 |

900 |

52.4 |

355.6 |

1.68 |

670 |

1.86 |

740 |

| ZYL1000 |

1000 |

58.2 |

355.6 |

1.68 |

740 |

1.86 |

830 |

| 355.6 Series Double chain & bucket |

| Model |

Bucket width(mm) |

Volume(L) |

Distance |

Speed(m/s) |

Capacity(m3/h) |

Speed(m/s) |

Capacity(m3/h) |

| ZYL600*2 |

600(2 pcs) |

70 |

355.6 |

1.68 |

880 |

1.86 |

980 |

| ZYL720*2 |

720(2 pcs) |

83.8 |

355.6 |

1.68 |

1060 |

1.86 |

1180 |

| ZYL800*2 |

800(2 pcs) |

93.2 |

355.6 |

1.68 |

1180 |

1.86 |

1320 |

| ZYL900*2 |

900(2 pcs) |

104.8 |

355.6 |

1.68 |

1340 |

1.86 |

1480 |

| ZYL1000*2 |

1000(2 pcs) |

116.4 |

355.6 |

1.68 |

1480 |

1.86 |

1660 |

| Remark:The capacity is calculated by the filling factor k=0.33 |

Material to be processed:______ Handling capacity:______t/h

Bulk Density: ______t/m3 Water content:______%

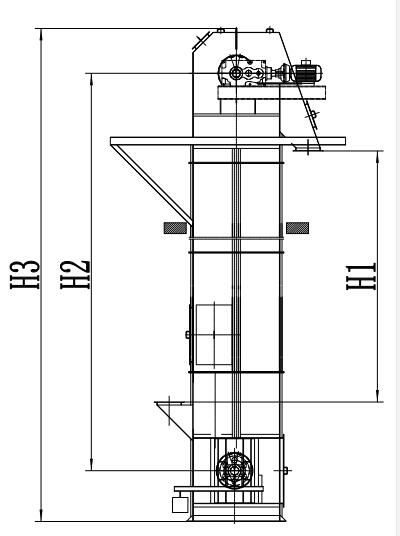

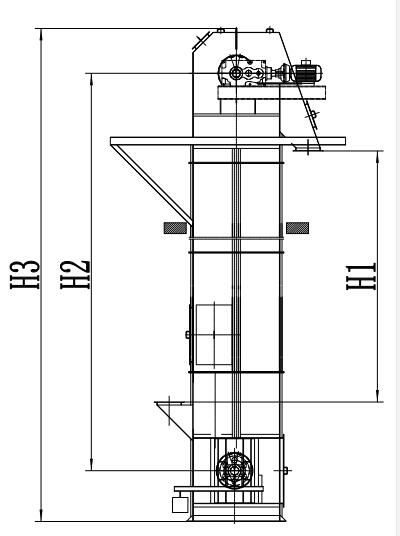

H1= Lifting height of the elevator = vertical distance from inlet to outlet):______

H2= Vertical distance of chain from the elevator head to tail:______

H3= Vertical distance from the ground to the top of elevator :______

Please be sure to give us the H1 ( lifting height of the elevator ), it can help our engineers to analyze, then we can supply the exactly advanced technology support and services).

Material temperature:______℃; Working environment temperature: ______ ℃

Material is corrosive or not:______ (Ps. Yes or No)

Max. granule size of the feeding material:______mm Max. granule’s percentage in whole material:______ %

Upstream equipment (using for feed the material): _____ Downstream equipment (using for discharge the material):______

Whether needing supporting equipment?______(Ps. Yes or No)

Working power supply: ______V ______HZ Quantity:______

.jpg)