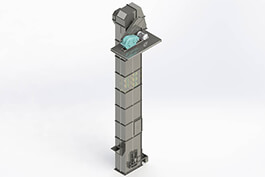

The chain bucket elevator is the product that has been introduced and developed by foreign advanced technology,suitable for vertical delivery of powder, granular and bulk materials,it can also improve the abrasive material,such as fly ash, slag, limestone, cement raw materials, cement clinker, cement, coal, dry clay, etc. Material temperature generally does not more than 250°.

The chain bucket is fixed on the high-strength chain as a traction part.When equipped with deep bucket, it is suitable for conveying dry, loose and powdery, granular,massive materials which having good flowability.When equipped with shallow buckets, it is suitable for powdered and granular materials which are slightly damp, easy to agglomerate, poor flowability.

High capacity vertical conveying

It adopts inflow feeding, inducing unloading, and large-capacity hopper intensive arrangement. There is almost no returning and excavation during material lifting, so there is less reactive power.

Extra heavy-duty design

The Bucket Elevator has less requirements on the type and characteristics of the material, not only can improve the general powdery and small granular materials, but also can improve the materials with high abrasion resistance. The sealing performance is good and the environmental pollution is less.

Highly reliable and durable

The operation reliability is good, the advanced design principle and processing method ensure the reliability of the whole machine operation, and the trouble-free time exceeds 20,000 hours. The lifting height is high. The hoist runs smoothly, so it can reach a higher lifting height.

Long service life

The feeding of the hoist is inflow type, no need to use the bucket to dig, and there is little squeezing and collision between the materials. The machine is designed to ensure that the material is less sprinkled during feeding and unloading, reducing mechanical wear.

WHY CHOOSE EXCT chain BUCKET ELEVATOR

chain BUCKET ELEVATOR APPLICATION INDUSTRY

.jpg) CHAIN BUCKET ELEVATOR MATERIAL

CHAIN BUCKET ELEVATOR MATERIAL

.jpg)

| THG Chain Bucket Elevator(Deep bucket)Technical Specifications |

| Model |

THG160 |

THG200 |

THG250 |

THG315 |

THG400 |

THG500 |

THG630 |

THG800 |

THG1000 |

THG1250 |

THG1600 |

| Capacity (m3/h) |

30 |

50 |

70 |

100 |

160 |

210 |

350 |

475 |

715 |

1120 |

1550 |

| Bucket |

Volume(L) |

2.6 |

4.1 |

6.5 |

10 |

16 |

25 |

40 |

64 |

102 |

161 |

255 |

| Pitch(mm) |

270 |

270 |

336 |

378 |

420 |

480 |

546 |

630 |

756 |

756 |

882 |

| Chain and bucket weight (kg/m) |

31 |

31.85 |

33.4 |

43.25 |

60.9 |

79.6 |

88.66 |

107 |

150 |

187.6 |

233 |

| Speed (m/s) |

0.93 |

0.93 |

1.04 |

1.04 |

1.17 |

1.17 |

1.32 |

1.31 |

1.47 |

1.47 |

1.47 |

| Max lift height(m) |

60 |

60 |

60 |

60 |

60 |

60 |

60 |

55 |

55 |

40 |

40 |

| Remark:1 The capacity is calculated by the filling factor k=1 |

| 2 The max lift height=Distance between Head and Tail Shaft |

| 3 The buckets capacity=buckets filled with the water |

| THG Chain Bucket Elevator(Shallow bucket)Technical Specifications |

| Model |

THG160 |

THG200 |

THG250 |

THG315 |

THG400 |

THG500 |

THG630 |

THG800 |

THG1000 |

THG1250 |

THG1600 |

| Capacity(m3/h) |

21 |

33 |

45 |

74 |

120 |

160 |

250 |

345 |

520 |

810 |

1110 |

| Bucket |

Volume(L) |

1.9 |

2.9 |

4.6 |

7.4 |

12 |

19 |

29 |

47 |

74 |

117 |

184 |

| Pitch(mm) |

270 |

270 |

336 |

378 |

420 |

480 |

546 |

630 |

756 |

756 |

882 |

| Chain and bucket weight(kg/m) |

31 |

31.85 |

33.4 |

43.25 |

60.9 |

79.6 |

88.66 |

107 |

150 |

187.6 |

233 |

| Speed(m/s) |

0.93 |

0.93 |

1.04 |

1.04 |

1.17 |

1.17 |

1.32 |

1.31 |

1.47 |

1.47 |

1.47 |

| Max lift height(m) |

75 |

75 |

75 |

75 |

75 |

75 |

75 |

70 |

70 |

55 |

55 |

| Remark:1 The capacity is calculated by the filling factor k=1 |

| 2 The max lift height=Distance between Head and Tail Shaft |

| 3 The buckets capacity=buckets filled with the water |

| NE Chain Bucket Elevator Technical Specifications |

| Model |

Capacity/(m3/s) |

Speed/ (m/s) |

Spindle Speed/ (r/min) |

Bucket |

Operation Part Quality/

(kg/m) |

| Volume/L |

Width/mm |

Pitch/mm |

| NE15 |

15 |

0.5 |

15.54 |

2.5 |

250 |

203 |

27.5 |

| NE30 |

32 |

16.45 |

7.8 |

300 |

305 |

35 |

| NE50 |

60 |

16.45 |

15.7 |

30 |

305 |

64 |

| NE100 |

110 |

14.13 |

35 |

400 |

400 |

89 |

| NE150 |

170 |

14.13 |

52.2 |

600 |

400 |

112.3 |

| NE200 |

210 |

10.9 |

84.6 |

600 |

500 |

134 |

| NE300 |

320 |

10.9 |

127.5 |

600 |

500 |

188 |

| NE400 |

380 |

8.3 |

182.5 |

700 |

600 |

205 |

| NE500 |

470 |

7.1 |

260.9 |

700 |

700 |

223 |

| NE600 |

600 |

7.1 |

330.2 |

700 |

700 |

274 |

| NE800 |

800 |

6.2 |

501.8 |

800 |

800 |

313 |

1.Which material to be handling:______

2.Handling capacity:______t/h.

3.Lifting height of bucket elevator(Ps:vertical distance from feed inlet to discharge outlet): ______m

4.Bulk Material Density: ______t/m3

5.Max. granule size of the material: ______mm

6.Max. granule’s percentage in whole material:______ %

7.Material temperature:______℃

8.What equipment is used to feed the material into the chain bucket elevator:______

9.What equipment is used to discharge the material from the chain bucket elevator:______

10.Working power supply: ______V ______HZ

11.Quantity:______

12.As everyone knows, the chain bucket elevator work with other equipment to form a process system, therefore, we will appreciate if you can provide us the preliminary design or hand-drawn sketch of the process system for our engineers reference.

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

(2).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)